The Impact of the High Proof Series Oak Alternatives in Whiskey:

Exploring Contact Time and Dosage Rate to Achieve Targeted Sensory ResultsAndrew Wiehebrink, Director of Spirit Research and Innovation, Independent Stave Company

INTRODUCTION

During an era of innovation, oak alternatives are becoming an important tool for spirit maturation. Oak alternative products may be toasted using different types of technology to impart traditional oak flavors or offer new flavors. They are also versatile in application, with numerous product formats and configurations available that may be applied to spirits during maturation or finishing to achieve a desired organoleptic profile.

This experiment explores the High Proof Series of oak alternatives developed by Oak Solutions Group for the spirits industries. Oak Solutions Group and its Research & Development team have over 75 years of combined experience in whiskey barrel maturation and oak alternative product development. The release of the High Proof Series further expands the options available to distillers by focusing on a variety of flavors desired in the spirits industry

EXPERIMENTAL DESIGN

This experiment measures the impact of four oak alternative products applied as a finishing process. Finishing is a technique utilized post maturation to add specific nuances or enhance the impact of the initial maturation period. In most circumstances, finishing is accomplished by introducing aged spirit to specific barrels or barrel alternatives for a time period determined by the producer – usually less than a year with American whiskeys.

The High Proof Series oak alternative products evaluated in this experiment were created by Oak Solutions Group to offer four different flavor targets.

Products include:

- Sweet Shoppe

- Spice Rack

- Rickhouse

- Charred Barrel

Each of these products is available in different configurations to fit different types of aging vessels. For the purposes of the experiment, barrel inserts and oak flavoring stix were used. Barrel Inserts are thread on a food grade LDPE (Low-Density Polyethylene) rod. Each insert measures 28” x 2.5” x 0.375. The number of inserts depends on desired dosage. Typically seven to ten inserts. Oak Flavoring Stix have 17 sections each containing two 8” x 1.25’ x 0.375” pieces which is approximately 8.5 square feet. The sections are separated and wrapped in mesh and easily adhere to a bung with an attached wire and screw. For additional information visit oaksolutionsgroup.com/configurations.

To evaluate the influence of the High Proof Series products in terms of 1) contact time and 2) dosage rate, the experiment was set up as follows using a total of 78 used whiskey barrels, all 53-gallon capacity:

- 6 control barrels with no oak alternative products added

- Barrels with Sweet Shoppe products:

- 6 barrels dosed at 6 g/L (5 stave inserts)

- 6 barrels dosed at 12 g/L (10 stave inserts)

- 6 barrels dosed with 1 quantity of oak flavoring stix at 7.65 g/L

- Barrels with Spice Rack products:

- 6 barrels dosed at 6 g/L (5 stave inserts)

- 6 barrels dosed at 12 g/L (10 stave inserts)

- 6 barrels dosed with 1 quantity of oak flavoring stix at 7.65 g/L

- Barrels with Rickhouse products:

- 6 barrels dosed at 6 g/L (5 stave inserts)

- 6 barrels dosed at 12 g/L (10 stave inserts)

- 6 barrels dosed with 1 quantity of oak flavoring stix at 7.65 g/L

- Barrels with Charred Barrel products:

- 6 barrels dosed at 6 g/L (5 barrel inserts)

- 6 barrels dosed at 12 g/L (10 barrel inserts)

- 6 barrels dosed with 1 quantity of oak flavoring stix at 7.65 g/L

One hundred and eight barrels were filled at the participating distillery on December 5, 2018 with an entry proof of 72.85% ABV. The 100% corn mash bill was an eight year old Canadian whiskey distilled to 94%. Samples were taken from each barrel every two weeks. These whiskey samples were analyzed using Gas Chromatography-Mass Spectrometry (GCMS) to measure the presence of key compounds extracted from the oak products that are influential to oak perception:

Vanillin

4-ethyl guaicol

5-methyl-furfural

Cis lactone

Eugenol

Furfural

Guaiacol

Syringe aldehyde

Trans isoeugenol

Trans lactone

In this report, the data is presented in graphs as a percent of the average. First, an average concentration was calculated for each compound. This was obtained by summing the concentrations from all samples in the experiment and dividing by the

number of samples. Next, the compound concentration of each individual sample in a data set was divided by the previously calculated average.

RESULTS AND DISCUSSION

Product Evaluation / Contact Time

The first section of data presented focuses on the GCMS analysis for each of the four products and compares the results at two, four and six weeks of contact time to the control.

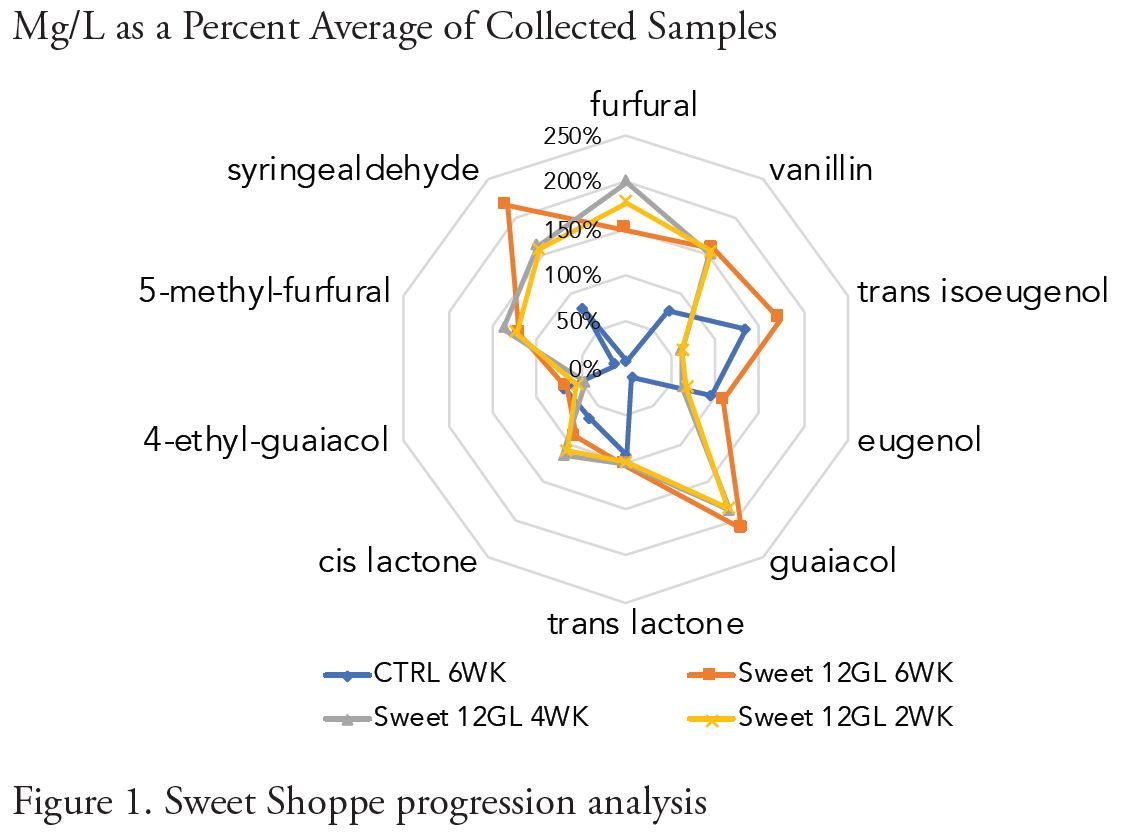

Sweet Shoppe

This product was developed by Oak Solutions Group to focus on confectionary characters, including caramel, vanilla and candied fruit, as well as rich flavor and a smooth mouthfeel. GCMS analysis presented in Figure 1 confirms:

- A significant increase in extractive concentration compared to the control whiskey.

- Notable spikes in vanillin, responsible for vanilla, and furanic compounds responsible for caramel and toasty character.

- By six weeks of contact time, guaiacol and eugenol compounds begin to have a stronger influence on the flavor profile. These compounds will add depth and complexity but will also reduce the perception of sweetness.

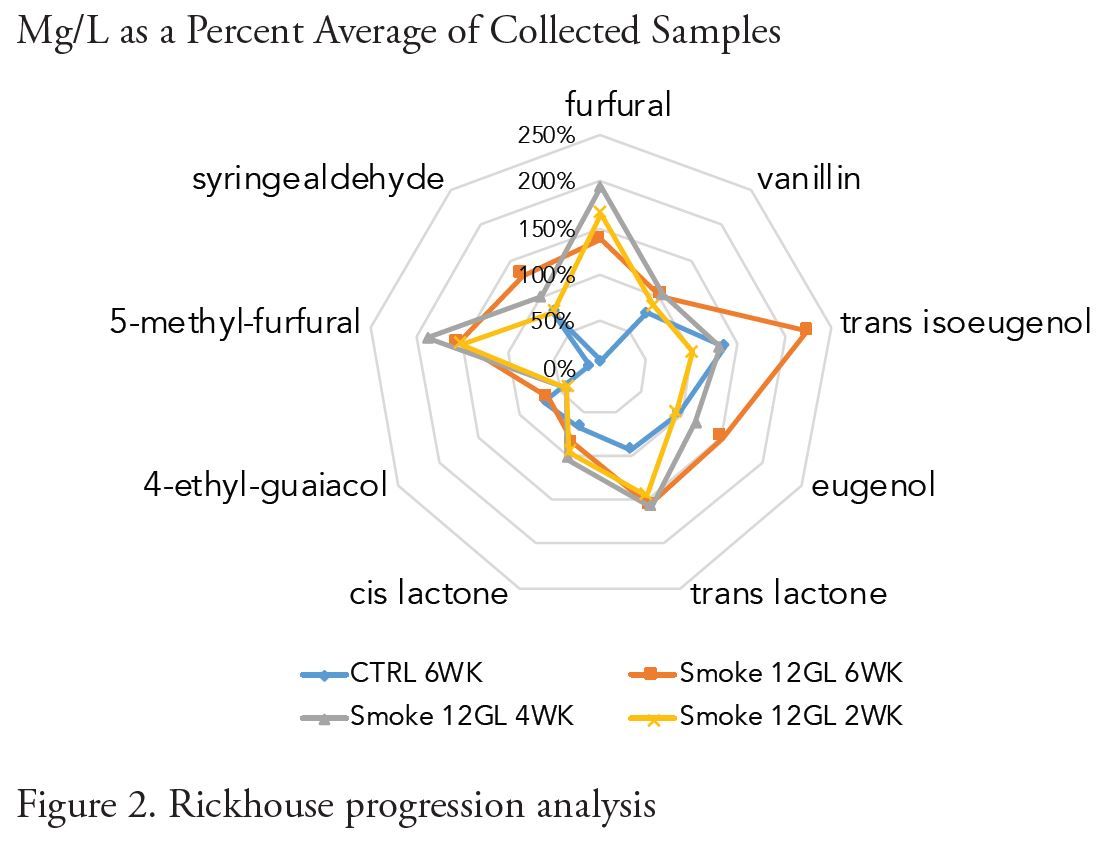

Rickhouse

Oak Solutions Group developed this product to center on fresh, toasted oak flavors with a touch of smoke along with honey and spice. GCMS analysis shown in Figure 2 indicates:

- A significant increase in extractive concentration compared to the control whiskey.

- Prominent spikes in syringaldehyde, furfural and 4-ethyl-guaiacol, which indicate a broad range of added flavor. Specifically, this signifies the addition of woody, smoky and toast characters.

- This product is high impact in the first four weeks of contact time. Sensory analysis is important to find the right balance.

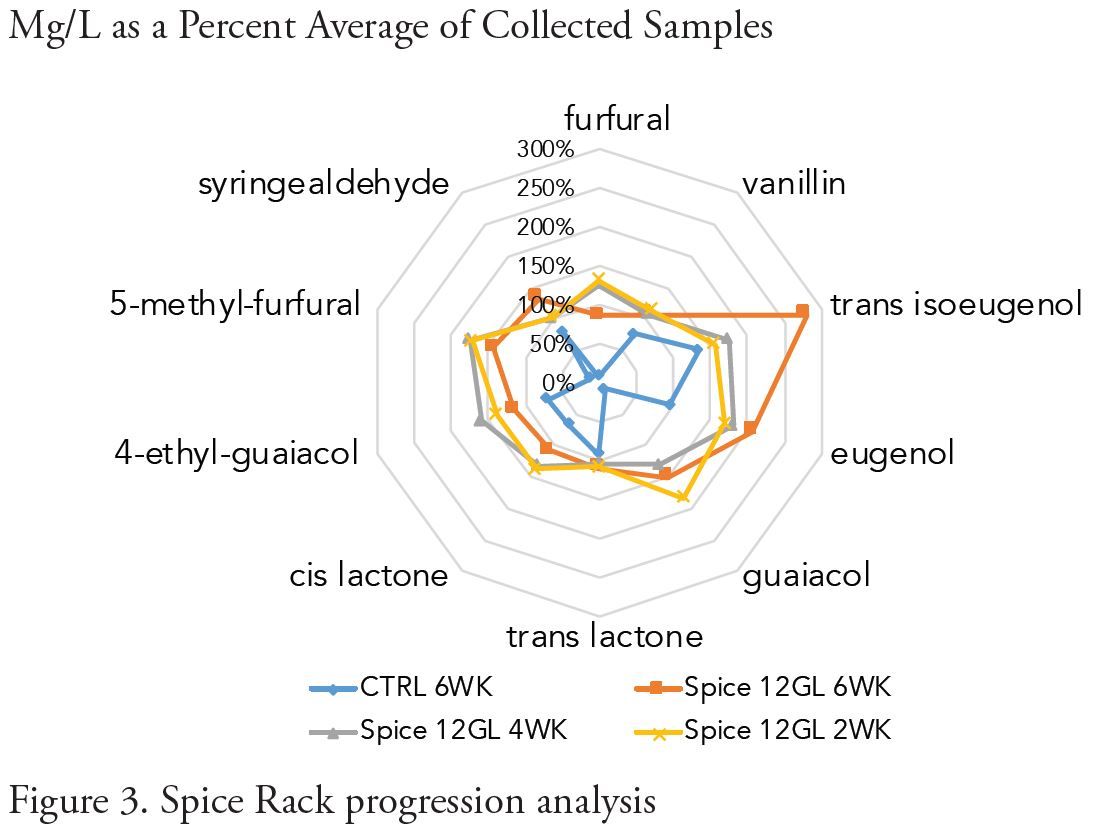

Spice Rack

This product was developed by Oak Solutions Group to offer a plethora of aromas and flavors, including baking spices, maple syrup and dried citrus. GCMS analysis of this product in Figure 3 confirms:

- A significant increase in extractive concentration compared to the control whiskey.

- Prominent spikes in both eugenol and isoeugenol, indicating a strong spice component in the flavor profile. Eugenols continue to increase in concentration over the extraction period of six weeks.

- Notable increases in guaiacol over the control whiskey. The presence of this compound suggests slightly smoky character will be extracted using this product.

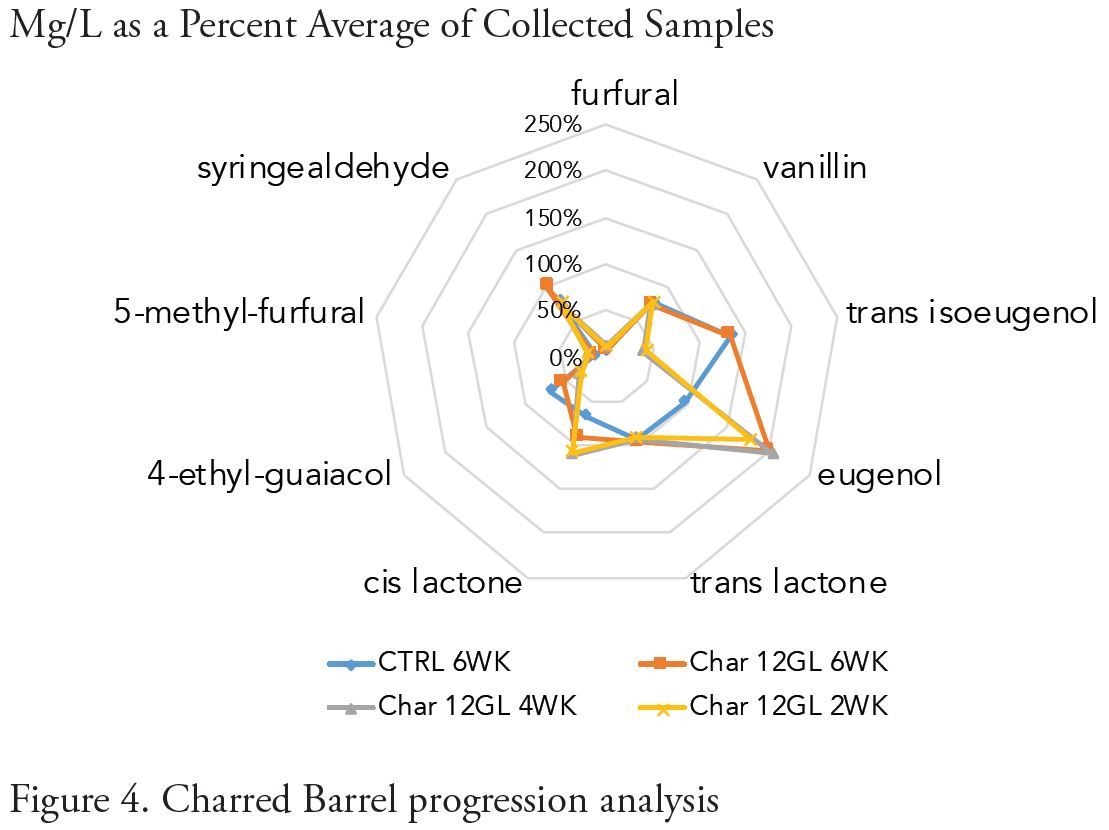

Charred Barrel

This product was developed by Oak Solutions Group to mimic some of the key flavor characteristics of a charred American oak barrel, including fresh oak, lactones and estery characters. GCMS analysis presented in Figure 4 shows:

- A moderate overall impact compared to the control whiskey.

- An increase in cis lactone during the first weeks of contact time followed by a slight reduction at six weeks.

- A prominent increase in eugenol, which signifies the addition of spice character to the whiskey.

- A low impact in the other lignin and hemicellulose-derived compounds such as furfural and vanillin, matching the mellow overall oak impact desired for this product.

Dosage Rate

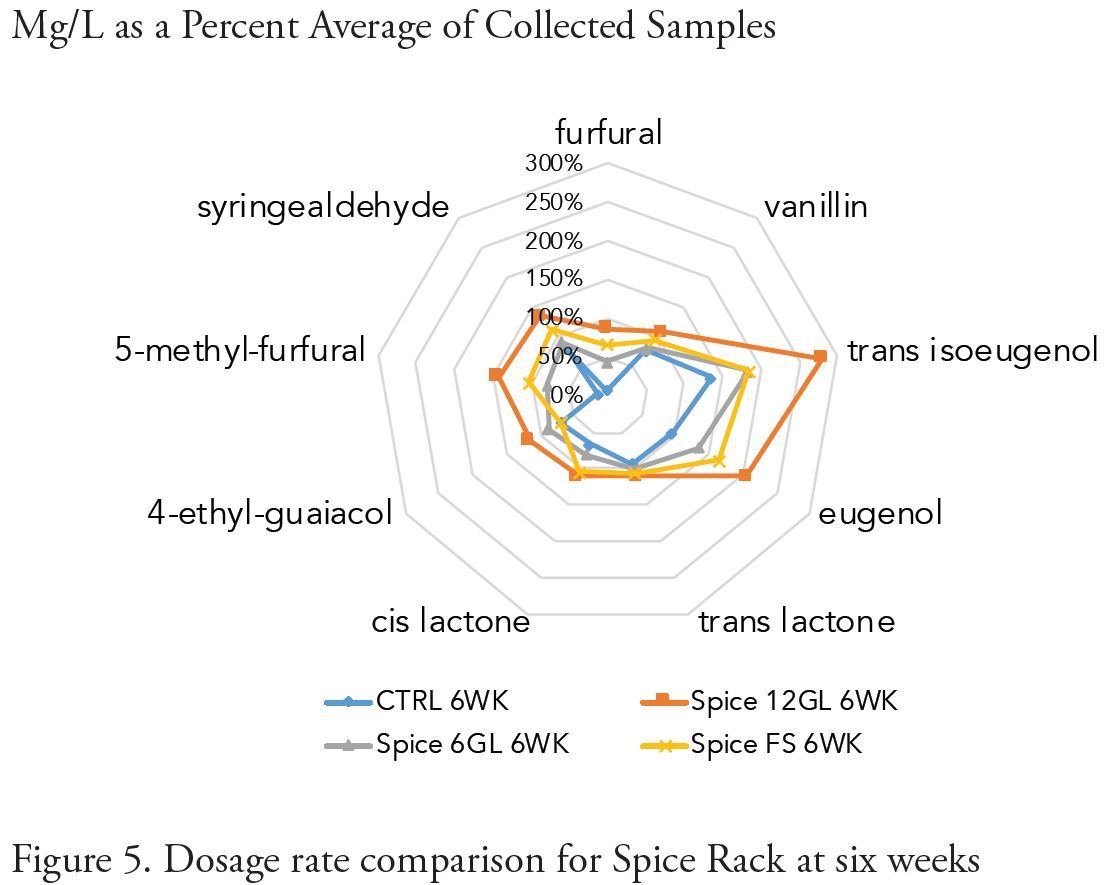

This experiment also explored how dosage rate of the oak products impacted the finished product. Figure 5 presents the data for the Spice Rack product at six weeks of contact time. Three different dosage rates were used: 6 g/L, 12 g/L and one set of barrels dosed with a single oak flavoring stix 7.65g/L.

Results

The dosage rate had a noticeable effect on the progression of extractive concentration.

- The barrel insert application at 12 g/L provides the largest increase in extractive concentration.

- The oak flavoring stix application provides the second largest increase, thereby indicating the increased surface area of this product in contact with the whiskey has a significant effect on flavor development.

CONCLUSION

This experiment validated oak alternatives as a useful tool to differentiate and distinguish base whiskeys or other matured distilled spirits. By utilizing finishing techniques such as those described in this document, producers can create multiple

products, with very different flavor profiles, utilizing a single liquid stream. This experiment also confirmed this can be done in a short period of time.

All products performed as intended. The first three products (Sweet Shoppe, Rickhouse and Spice Rack) delivered significant amounts of targeted flavor compounds, while the Charred Barrel product remained versatile, not targeting a specific flavor but rather bringing balanced additional oak impact to the base whiskey.

The data also exhibits the significance of contact time and dosage rate as critical considerations to developing the organoleptic profile of a spirit during finishing.

- The amount of contact time between the product and the spirit will lead to different nuances in the spirit.

- A longer contact time is not necessarily proportional to a larger increase in extractive concentration.

- During application of the High Proof Series products, the sensory impact will change from week to week, and certain products will induce changes more quickly than others. It is recommended to monitor the flavor development process regularly during the anticipated contact time and to remove the application once the desired profile is achieved.

- Dosage rate may also be adjusted to achieve the desired result from the product being used. Oak extractives can be increased through a higher dose rate or selecting a configuration with increased surface area.

APPENDIX

| Compound | Aroma |

|---|---|

| furfural | heavier toast, sweet, woody, baked bread, slightly phenolic |

| acetyl furan | sweet, almond, balsamic, cocoa, caramel, coffee, nutty |

| 5-methyl-furfural | caramel, spicy, maple |

| furfuryl alcohol | bready, musty, burnt, sweet |

| guaiacol | smoke, phenolic, medicinal, meaty |

| trans oak lactone | coconut, celery |

| 4-methyl-guaiacol | sweet, candy, spicy, clove, leathery, smoky |

| cis oak lactone | sweet, spicy, coconut, vanilla |

| maltol | sweet, caramel, cotton candy, marshmallow, jammy, fruity |

| o-cresol | phenolic, musty, medicinal |

| phenol | phenolic, plastic, rubbery |

| furaneol | sweet, caramel, strawberry, brown sugar |

| 4-ethyl-guaiacol | spicy, smoky, bacon, phenolic clove |

| p-cresol | phenolic |

| m-cresol | medicinal, woody, leathery, phenolic |

| 4-ethyly-phenol | smoky, phenolic |

| 4-vinyl-guaiacol | dry, woody, cedar, roasted peanut |

| eugenol | sweet, clove, spicy, woody, allspice, ham |

| syringol | smoky, bacon, powdery, woody, meaty |

| trans-isoeugenol | spicy, carnation, floral, sweet |

| cis-isoeugenol | spicy, clove |

| 5-hydroxymethyl | fatty, buttery, waxy, caramel, hay, tobacco |

| furfural | |

| methoxy eugenol | roasted, meaty, burnt, bacon, ham |

| vanillin | vanilla, creamy, chocolate |

| vanillin-d3 | vanilla, minty |

| methyl vanillate | warm, spicy, vanilla, carnation |

| ethyl vanillate | phenolic, burnt, smoky, powdery, metallic |

| syringaldehyde | sweet, woody, creamy, cocoa, green, fresh |

| coniferyl aldehyde | cinnamon, woody |

CREDITS

The experiment was conducted in 2018/2019 by Independent Stave Company and Oak Solutions Group in partnership with JP Wiser’s

of Hiram Walker & Sons Ltd, with special contributing efforts from:

Independent Stave Company

Andrew Wiehebrink, Director of Spirit Research and Innovation

Oak Solutions Group

Kyle Sullivan, Global Managing Director

Amy LaHue, Oak Solutions Specialist

JP Wiser’s

Don Livermore, Master Blender - JP Wiser’s

Laura Bezaire, Bulk Spirit Sales - Hiram Walker & Sons Ltd

Darren Taylor, Bulk Spirits - Hiram Walker & Sons Ltd